Motor Oil Basics

A Beginner’s Guide to Motor Oil: The Basics About Motor Oil You Need to Know.

Knowing the basics of motor oil is important. These basics will help you better understand where oils come from, what they must do daily, how they are classified and is synthetic oil better. Our goal is to help you better understand the basics of oils so you can make the best choice for your vehicles and equipment. t

Let’s Start!

What is motor oil?

Motor oil is one of the most important factors in your engine’s performance and longevity. Simply put, it’s the lubricant that prevents all those metal parts from tearing each other apart or welding themselves together into the world’s coolest boat anchor. Without motor oil, your engine would destroy itself in a matter of seconds.

What is motor oil made from?

Motor oil contains two fundamental components: base oils and additives. The two work in tandem to produce the final product you put in your engine. Think of coffee as an analogy – the base oil is the water and the additive package is the coffee beans.The base oils comprise the largest portion of the oil. They lubricate internal moving parts, absorb heat and seal the piston rings.

Motor oil base oils can be composed of :

- petroleum (aka Dinosaur oil)

- chemically synthesized materials

- a combination of synthetics and petroleum (called semi-synthetic or synthetic blend).

Petroleum (or conventional) base oils are refined from crude oil. Contaminating elements such as sulfur, nitrogen, oxygen and metal components such as nickel or vanadium are inherent to crude oil and cannot be completely removed through the refining process. The oil refining process separates the various types of molecules in the oil by weight leaving molecules similar in weight, but dissimilar in structure. This results in reducing performance of the oil.

Synthetic base oils, on the other hand, are highly engineered to include only beneficial molecules. As such, they contain no contaminants or molecules that don’t serve a designed purpose. Their versatility and pure, uniform molecular structures impart properties that provide better friction-reduction, optimum fuel efficiency, maximum film strength and extreme-temperature performance. These are properties that conventional lubricants just can’t touch.

Motor oil additives

The various chemicals that comprise a motor oil’s additive system provide the following:

- anti-wear

- anti-foam

- corrosion protection

- acid neutralization

- viscosity maintenance

- detergency ( ability to clean internal parts) and

- dispersancy properties ( ability to keep dirt suspend in oil for removal during an oil change).

A few examples of chemical additives include zinc, phosphorus and boron. Striking the perfect balance of the proper additives in relation to the base oil is a tough balancing act for oil formulators, especially as vehicle engine technology grows more demanding and sophisticated. In other words, smaller engines producing more horsepower while trying to increase fuel mileage with reduce emissions.

What functions must a motor oil do?

Modern motor oils are highly specialized products carefully developed by engineers and chemists to perform many essential functions. Here are 7 functions a motor oil must do.

Minimize Friction

Lubricants reduce contact between components, minimizing friction and wear. They accomplish this by leaving a thin film on the surfaces of parts. The ability of an oil to remain “stuck” to a part and coating it after long periods of “sitting still” is a major preventer of wear during a “cold start”. A “cold start” refers not just to cold temps, but also refers to engines that haven’t been started in a while, like overnight. Studies have shown that cold starts are where most engine damage occurs.

Clean

Lubricants maintain internal cleanliness by suspending contaminants within the fluid or by preventing the contaminants from adhering to components. Base oils possess a varying degree of solvency that assists in maintaining internal cleanliness. Solvency is the ability of a fluid to dissolve a solid, liquid or gas.

While the solvency of the oil is important, detergents and dispersants play a key role. Detergents are additives that prevent contaminants from adhering to components, especially hot components such as pistons or piston rings. Dispersants are additives that keep contaminants suspended in the fluid. Dispersants act as a solvent, helping the oil maintain cleanliness and prevent sludge formation.

Cool

Reducing friction minimizes heat in moving parts, which lowers the overall operating temperature of the equipment. Lubricants also absorb heat from contact surface areas and transport it to a location to be safely dispersed, such as the oil sump.

Fun Fact: Lubricating an engine requires a very small amount of motor oil compared to the amount needed to ensure proper cooling of all these internal parts.

Seal

Motor oil acts as a dynamic seal in locations like the piston ring/cylinder interface. A dynamic seal helps keep combustion gases in the combustion chamber, which maximizes horsepower and helps prevent hot gases from contaminating the motor oil in the sump.

Dampen Shock

A lubricant can cushion the blow of mechanical shock. A highly functional lubricant film can resist rupture and absorb and disperse these energy spikes over a broad contact area. As the mechanical shock to components is dampened, wear and damaging forces are minimized, extending the component’s overall operating life.

Protect Against Corrosion

A lubricant must have the ability to prevent or minimize internal component corrosion. Lubricants accomplish this either by chemically neutralizing corrosive products or by forming a barrier between the components and the corrosive material.

Fun Fact: Motor oil has no natural ability to resist rust and corrosion; those properties must be added through use of motor oil additives.

Transfer Energy

Because motor oil is incompressible, it makes an excellent energy-transfer medium, such as when used with hydraulic valve lifters or to actualize components in an engine with variable valve timing.

What is viscosity?

What is viscosity?

Viscosity refers to the oil’s resistance to flow and is the most important property of an oil. The viscosity of oil varies with changes in temperature – thinner when hot, thicker when cold.

Although oil must flow at cold temperatures to lubricate the engine at startup, it must also remain thick enough to protect the engine at high operating temperatures. When an oil is used at a variety of temperatures, as with most engines, the change in viscosity should be as minimal as possible.

Viscosity Index (VI)

Wouldn’t it be handy to have a number that indicated the oil’s viscosity change? We do, and it’s called the Viscosity Index (VI). It is measured by comparing the viscosity of the oil at 40°C (104°F) with its viscosity at 100°C (212°F). The higher the VI, the less the viscosity changes with temperatures changes and the better the oil protects the engine. Synthetics typically have a higher VI than conventional oils.

SAE Viscosity Grades

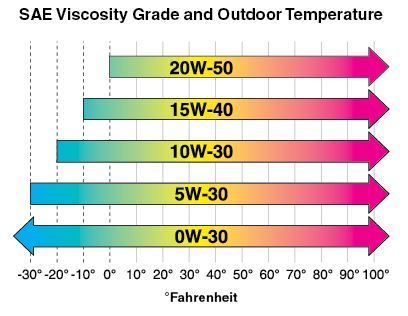

The Society of Automotive Engineers (SAE) has developed several viscosity classifications or grades, such as 5W-30, 10W-40 and 15W-50.

These viscosity grades designate the specific ranges in which the particular oil falls. The “W” indicates it is suitable for use in cold temperatures. (Think of the “W” as meaning “Winter.”) The classifications increase numerically; the lower the number, the lower the temperature at which the oil can be used for safe and effective engine protection. Higher numbers reflect better protection for high-heat and high-load situations.

The overwhelming majority of oils today are multi-viscosity, meaning they behave differently at different operating temperatures to provide the best of both worlds – good cold-flow when the temperature drops and reliable protection once the engine reaches operating temperature. For example, a 5W-30 motor oil performs like an SAE 5W at 40ºC and an SAE 30 motor oil at 100ºC.

How is gasoline motor oil classified?

API Classification System

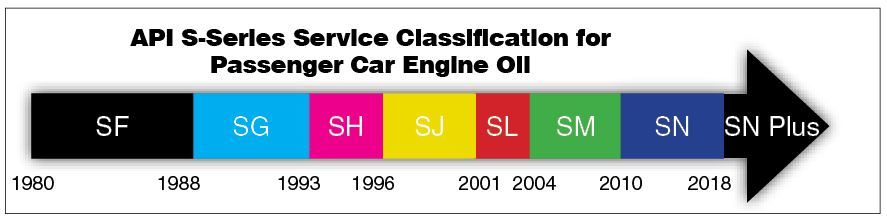

The American Petroleum Institute (API) developed a classification system to identify oils formulated to meet the different operating requirements of gasoline and diesel engines. The API system has two general categories: S-series and C-series.

S-series service classification

The S-series service classification emphasizes oil properties critical to gasoline engines. When an oil passes a series of both bench tests and engine tests (API Sequence tests), it can be sold bearing the applicable API service classification. The classifications progress alphabetically as the level of lubricant performance increases. Each classification replaces those before it. Oils meeting the latest API classification, API SN-PLUS, may be used in any engine calling for it or a previous API specification unless otherwise specified.

The API SN-PLUS category is the most recent classification, replacing those before it. SN-PLUS oils are designed to provide…

- Improved oxidation resistance

- Deposit protection

- Maximum fuel economy

- Emissions-system performance

- Resistance to a new type of engine knock called low-speed pre-ignition (LSPI)

How is Diesel Engine Oil Classified

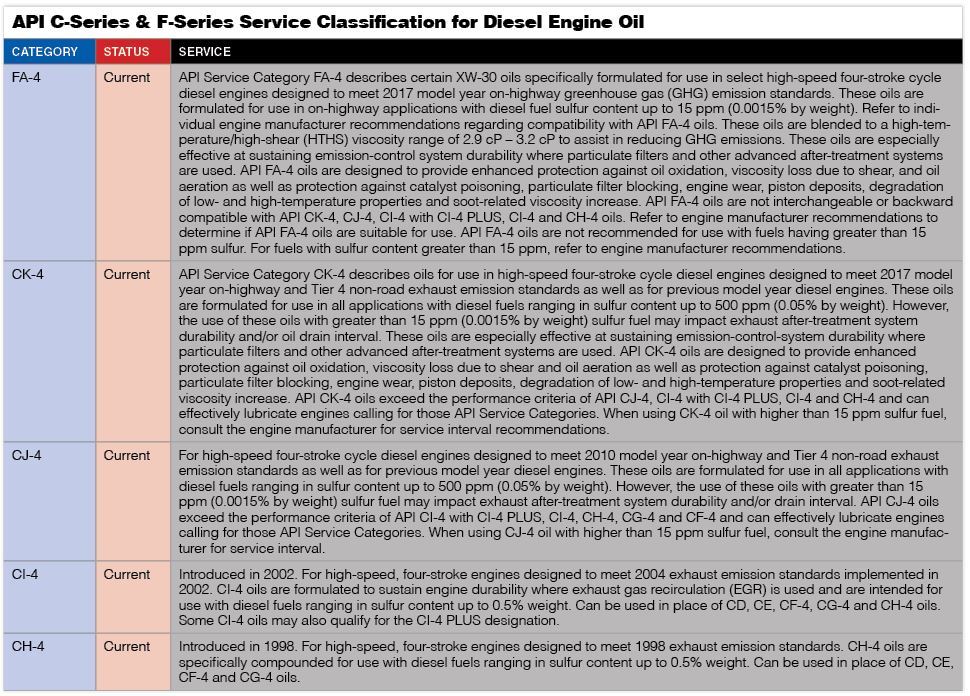

C-series classifications

C-series classifications pertain to diesel engines and include those shown below. Not all C-series classifications supersede one another. Note the new FA-4 classification, which pertains only to some 2017 and newer diesel engines. The FA-4 classification was introduced primarily to help maximize fuel economy in over-the-road trucks.

What’s the key takeaway?

That’s a lot of information, but it boils down to this: motor oil is more than a commodity. It’s a vital part of your engine’s longevity and performance. As such, it pays in the long run to use the best oil for your vehicle. The initial price of a high-quality synthetic motor oil may be more, but the lifetime cost can be far less compared to conventional oil, especially if you practice extended drain intervals.